Model: Zigzag servo press feeder

Place origin: China

Warranty date: 1 year

Certification: CE

Installation and debugging: Engineers onsite technical support is available.

Package: plywood case/film

Price terms: FOB SHENZHEN or other Chinese port etc.

Payment terms: T/T, L/C etc.

MOQ: 1 set

Delivery: 30-60 days

Application: to realize metal coil automatic punching/cut to length/blanking etc., widely used for working with punch press /power press /press brake/ hydraulic press machine/shearing machine etc.

Introduction

PRESS FEEDER FOR KITCHENWARE STAMPING LINE is built for blanking KITCHENWARE STAMPING from coil with the aim of reducing the scrap quantity by exploiting the whole width of the coil.

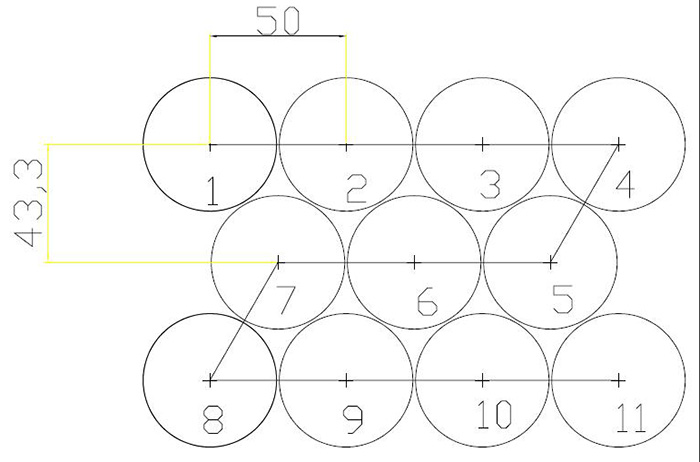

SCRAP REDUCTION

At first, kitchenware stamping line has been designed TO EXPLOIT THE WHOLE WIDTH OF THE COIL, reducing to the minimum distance to the strip edges,with a consequent REDUCTION OF THE SCRAP QUANTITY. Generally, we use 2mm as the distance. This reduction is realized avoiding the use of expensive and low flexible multiple dies.

AVOID ANY FURTHER WORKING PHASE

Since feeder for kitchenware can blank the whole width of the strip, with this technology is therefore possible TO REDUCE FURTHER WORKING PHASES, such as the reduction of the coil into coils of smaller width (=slitting),then save further costs and the possibility of damaging the coil surface (especially with aluminum ). This mostly applied in press feeder for kitchenware and rotor and stator automatic stamping etc.

FLEXIBILITY

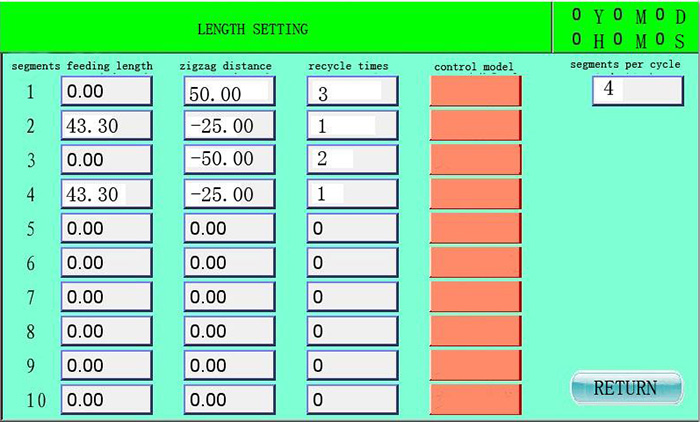

LOW DOWN TIMES: when change the production size (diameter), only change die and change the setting of the HMI.

WIDE PRODUCTION RANGE: the same line can blank different material, without any change or modification. The disk layout setting in the strip is no limit. Any punching path can be set by user.

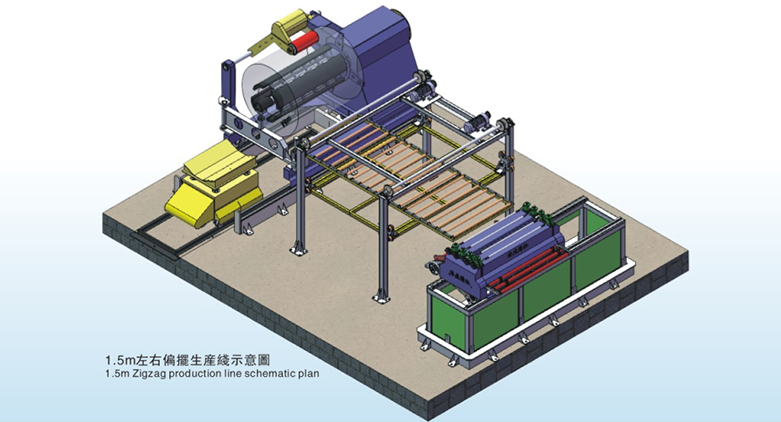

Layout of Press Feeder -Kitchenware Stamping Line

Composition of The Press Feeder Line

1500mm Heavy Uncoiler with Zigzag Movement

10T Automatic Loading Car

Material Guide and Support Bridge

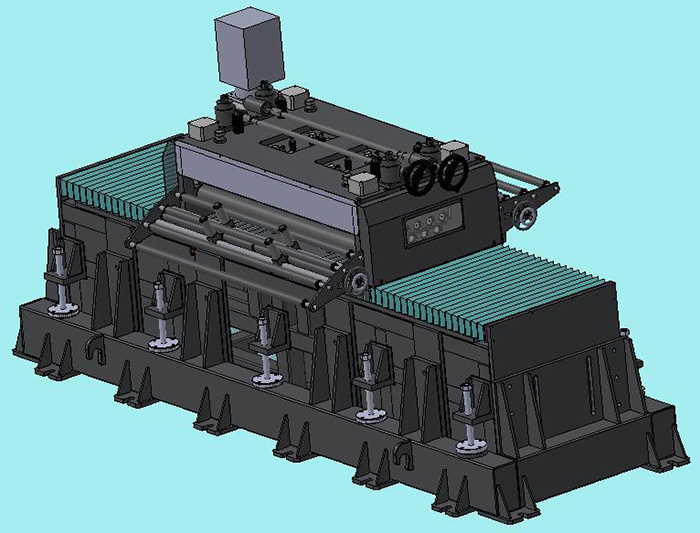

Straightener Feeder

Straightener controlled by motor with inverter.

Feeding material and swing move controlled by servo motor.

Electrical Control System

Pneumatic system

Lubrication system

Key parameter of the machine

Feeding length: 50mm—10000mm

Feeding tolenrance:200mm±0.05mm 、300mm±0.1mm 、700mm±0.15mm

Zigzag tolerance: L=200mm±0.05mm 、500mm±0.2mm 、1000mm±0.3mm

Punching speed: 30~45(depends on the diameter of the disc)

Inspection standard: 0.5mm thinkness stainless steel